Did you know that CooperVision carries more than 30,000 SKUs or individual parameter/lens combinations in silicone hydrogel material? That’s more than double the options of our nearest major competitor (Figure 1). What does this mean for you? Increased confidence that there is a CooperVision silicone hydrogel lens available for nearly every wearer that walks into your practice.

Figure 1. Comparison of SKUs of Major Contact Lens Manufacturers in Silicone Hydrogel Material.[1]

Biofinity® contact lenses account for the majority of these lens combinations. While the Biofinity lens started out as simply a spherical lens offering, the range has expanded significantly over the years to include toric, multifocal, and most recently, extended range offerings in both sphere and toric designs. Having an unrivaled range of contact lenses in silicone hydrogel material did not come about accidentally. CooperVision has made significant investments in manufacturing capability, logistics, and technology in order to be able supply this vast range of contact lens products.

To learn more about the history of Biofinity we sat down with Guy Whittaker, Senior Vice President of Global Marketing, who has been part of the Biofinity product development process since the beginning. He gave the Biofinity material its name and has been a happy Biofinity wearer since 2005, when the lens was first available in the United States. As a high myope and an optometrist, he appreciates the ocular health benefits of the Biofinity® material’s extremely high oxygen permeability and has also enjoyed the excellent visual acuity of the aspheric optics in the sphere lens, and, more recently, the Balanced Progressive® technology in the Biofinity Multifocal.

When was your first encounter with what ultimately became the Biofinity product line?

Guy Whittaker: In 2003 I met with the R&D team to review various material options and characteristics, for a new contact lens product. One of these materials eventually became Biofinity.

Biofinity put CooperVision (then Ocular Sciences) on the map as a contact lens manufacturer. In the early days of product development/commercialization, was it already clear how different Biofinity was from the other silicone hydrogel materials on market?

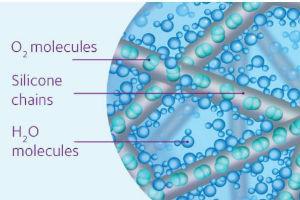

GW: Biofinity was very different from other silicone hydrogel materials on the market as it was a naturally wettable material, it needed no coatings or internal wetting agents, and had a lower modulus than we’d seen in the early, high Dk, silicone hydrogel materials. This resulted in a very comfortable lens, reduced risk of things like CLAPC (contact lens associated papillary conjunctivitis) which we’d seen on some of the earlier silicone hydrogel lenses[2] while giving great wettability and oxygen permeability. It was a real game changer.

Q: Biofinity remains one of CooperVision’s most memorable brands, what led you to choose the name “Biofinity”?

GW: The name is a play on ‘bio’ which is Greek for life and infinity – well understood in the optical profession. I did get annoyed early on when people mis-pronounced it Bioinfinity but I haven’t heard that happen for at least 10 years as it’s now such a well-known and respected brand.

Q: What was it like at OSI/CVI during the early days after Biofinity launch? What were some of the key obstacles that had to be overcome as a relatively small company rapidly grew with the launch of what would become a blockbuster product?

GW: The biggest challenge we had was being able to scale up production quickly enough, as from the outset there was a big demand for the product with the recognition of how well it performed on eye. The market was changing from one in which silicone hydrogels were used only as extended or continuous wear to one in which silicone hydrogels were the standard of care. Many hydrogel wearers were being refitted into Biofinity and demand surged. Another long-time CooperVision employee, Steve Mathieson, now head of European manufacturing, was responsible for the Biofinity manufacturing process at that time.

Q: If Biofinity put us on the map, it was definitely the Biofinity toric that made CooperVision what it is today. Tell me a little bit about the efforts to create and launch the BF toric. What was the biggest surprise from this effort?

GW: We already knew we had a great material in Biofinity, developing the toric meant combining the material with our proven Optimized Toric Lens Geometry™ design. We did make some tweaks to the design – we knew that while the toric design stabilized incredibly well - in some of the higher Rxs wearers complained of glare and halos so when we developed Biofinity toric we took the opportunity to make some changes in certain powers to increase the optic zone size. The combination of the material and design were an instant hit. The popularity of the team was also helped by the fact that we launched a wide range of parameters at the start. We’ve since increased the parameter range further, adding the XR toric range to allow practitioners to fit pretty much any astigmat that comes into their office.

The Biofinity MF product line is unique in the MF space as it offers both a center-distance and center-near design. It gives ECPs tremendous flexibility to optimize vision for their patients. Where did this idea of having two different MF designs come from? What were some challenges in bringing this product to life?

GW: The MF design was a design that CooperVision had been using on the Frequency MF and later on the Proclear MF lenses – so we know it was a design that worked well giving good near, intermediate and distance vision. Having 8 different add options (4 center near and 4 center distance) allows the practitioner to fine tune the Rx to the needs of the wearer. Given the success of this design it made sense to combine it with the benefits of the Biofinity material and hence Biofinity MF was launched.

Biofinity is a flagship product family for CooperVision that now encompasses sphere, toric, multifocal and extended parameter ranges, what is the highlight of this journey, from your perspective?

GW: Seeing Biofinity go from being an idea, selecting the right material options and properties, combining it with so many class leading designs to a world leading brand has been very exciting. It also enabled me to work closely with colleagues in manufacturing, regulatory and quality, operations as well as R&D to appreciate the massive amount of work, development and continuous improvement that goes into making what you could view as a simple contact lens. The attention to detail from all these groups is really what has led to the success of Biofinity.

And the journey hasn’t ended, we launched Bioinfity Energys and we continue to work to expand our offering allowing even more wearers to benefit from Biofinity.

Despite rapid growth in the 1 day modality, the monthly modality continues to be a key segment in many markets including the U.S. (where it is still the largest share of fits). Looking into your crystal ball what is your outlook for the future of the 1-month modality, and the Biofinity family specifically?

GW: Even through we’ve seen a big move to 1 Day lenses in the US over the last few years (the move to 1 Day lenses has already happened to a large extent in Europe and Japan) we continue to see Biofinity growing. Part of that growth is coming from new wearers, part from upgrades from FRP hydrogel lenses and partly because of the unique designs that are available in Biofinity with a very wide range of torics and MF, the XR (high powers in sphere and toric) and innovative designs like Biofinity Energys. So while the 1 Day segment will continue to grow in the US I’d see Biofinity also continuing to grow.

Any closing thoughts you’d like to make about the history of Biofinity and its continued bright future?

GW: It’s amazing that an idea from a material scientist over 15 years ago has been developed into a class leading product, and while the material still stands for natural wettability, comfort and high oxygen transmissibility, the breadth of the designs has increased so much allowing so many more people to benefit from consistent, clear vision every day. There’s much work going on behind the scenes to further develop Biofinity and the range so a lot of exciting things to come over the next few years.

The Biofinity material started out by redefining what a silicone hydrogel material could be, in terms of material properties. In the years that have followed we’ve leveraged our successful designs in toric and multifocal to expand the product line, and more recently have launched the extended range products in both sphere and toric to create a portfolio that is unmatched in range. But the innovation doesn’t stop there, most recently, we’ve added the Energys design with DigitalBoost™ in order to help your patients keep up with their busy lifestyles on-screen and off-screen (Figure 2). And the innovation continues as we continue to work to expand our offering allowing even more wearers to benefit from Biofinity.

Figure 2. The Biofinity Product Line.

For more information on the Biofinity family line of products go to the website below or speak to your local CooperVision sales representative. https://coopervision.com/practitioner/our-products/biofinity-family