Doctor, I left these lenses in my car. Are they alright?

You may have heard this question before from your patients and wondered about the answer? Not only can contact lenses (CL) and contact lens solutions (CLS) encounter extremes of temperature when stored improperly by wearers, but sometimes this can happen during shipping or transport of lenses from our distribution centers to your practices. CooperVision invests in fundamental research into various aspects materials science. This was one question that we wanted to be able to help you answer.

The results of how extreme temperature exposures can impact properties of Contact Lenses and Contact Lens Solutions were recently presented at the American Academy of Optometry in Orlando, Florida.

We’ve summarized the key messages from this poster below.[1]

In this study, extreme temperature conditions, including high and low temperature extremes and humidity, were simulated in order to see if contact lenses and CLSs would remain stable to these exposure conditions. The results showed that contact lenses and CLSs were not negatively impacted by these conditions and this should give confidence to ECPs and consumers that their contact lenses and solutions should stay viable and usable should they be exposed to temperature extremes during transit (provided the primary packaging is not compromised).

Specifically, we tested the following temperature conditions for CLs and CLSs, respectively.

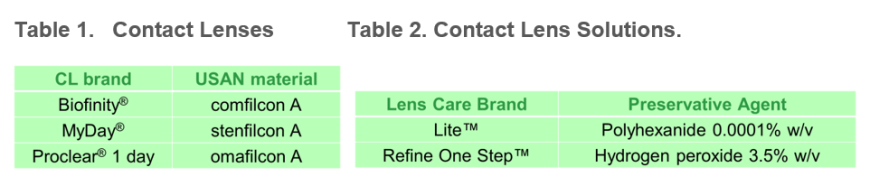

- Spherical silicone hydrogel and hydrogel CLs (Table 1, CooperVision, Inc.) in sealed primary packaging underwent exposure to extreme temperature conditions

- 45°C (113°F) for 3 months[2]

- -50°C (-58°F) for 72 hours, then thawed out at room temperature

- To assess the performance of CL care products (Table 2, CooperVision, Inc.), accelerated condition stability studies were conducted with exposure to temperature extremes to replicate hot and cold conditions:

- 40°C (104°F), 75% relative humidity for a minimum of 72 hours

- -18°C (-0.4°F), uncontrolled humidity for a minimum of 72 hours

Tables 1 and 2. Products Tested for Stability Under Extreme Temperatures.

As summarized in the introduction, the study found that all contact lenses evaluated were within approved tolerances for the parameters measured (base curve (BC), diameter (dia), water content (WC) and power (BVP)) after exposure to high and low temperature extremes[3]. Additionally, all lens care product formulations evaluated met specifications for pH, osmolality, disinfection efficacy and preservative efficacy after exposure to both high and low temperature extremes[4].

These results can help add confidence in the information you give to the users of some of CooperVision's most popular products who might accidentally leave their lenses in their car– summer or winter.

[1] “Tolerance of a Range of Soft Contact Lenses and Lens Care Products to Temperature Extremes”. Sulley, A.; Ward, R.; Riggs, P. Fall 2019 American Academy of Optometry National Meeting.

2 BS EN ISO 11987:2012 – Ophthalmic optics – contact lenses. Determination of shelf life

[3] All evaluated lens parameters were within approved tolerances (BC ±0.2mm, dia ±0.2mm, WC ±2% and power (BVP) ±0.25D) as based on ISO standards:

- BS EN ISO 18369-3:2017 – Ophthalmic optics - contact lenses. Measurement methods

-BS EN ISO 18369-4:2017 – Ophthalmic optics – contact lenses. Physicochemical properties of contact lens materials

-BS EN ISO 18369-2:2017 – Ophthalmic optics – contact lenses. Tolerances

[4] Shelf life studies were conducted with the CL care products in accordance with ISO standard ISO 13212:2014 (Ophthalmic optics - Contact lens care products - Guidelines for determination of shelf-life)